ISO 9001-Certified Jufeng Paper Refiner Disc Manufacturing Factory Special Report

2025-06-28

1. Introduction

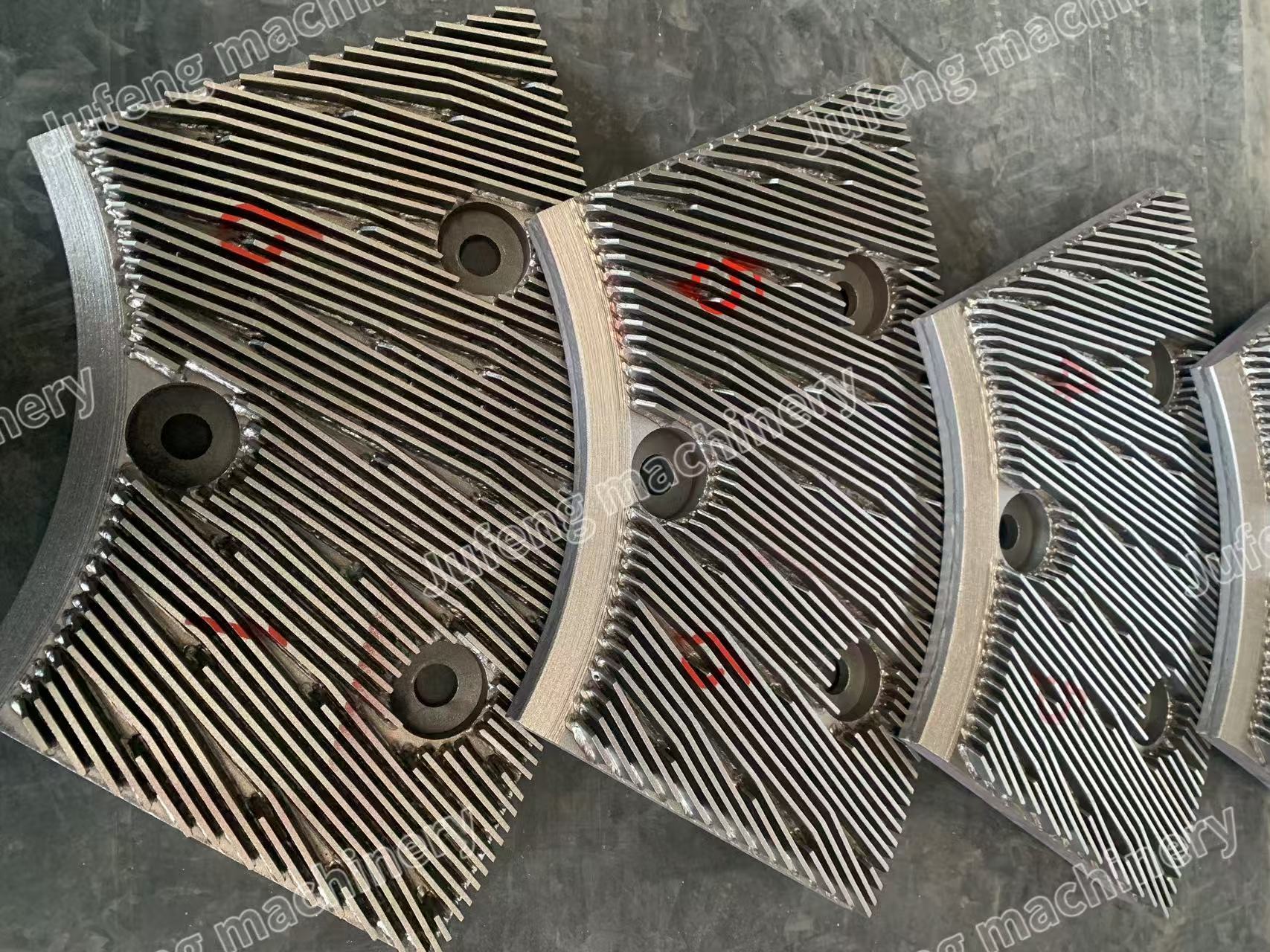

- Function: The Refiner Disc is a critical component in papermaking machinery, utilizing mechanical action (shearing, crushing, stretching) to process pulp fibers, ensuring optimal fiber characteristics for paper quality.

- Key Feature: Over 100 customizable tooth profiles tailored to different pulps, refining stages, and production requirements.

2. Types

-Stainless Steel Welding Refiner Disc: Manufactured by welding process.

- Milling Discs: Precision-machined for specific applications.

- Compatibility: Compatible with major brands (Valmet, Andritz, Voith) and diverse machinery models.

3. Applications

- Used in:

- Double Disc Refiners (pulp lines).

- High Consistency Refiners.

- Defibrators (MDF production).

- Heat Dispersers and Deflakers.

4. Raw Materials

-Material Type ,Hardness, Properties

-wear-resistant stainless steel , 48 - 52HRC

-Customized for specific needs

5. Key Advantages

- Durability: High wear resistance, impact toughness, and extended service life.

- Quality Assurance:

- Pre-shipment tests (hardness, destructive, dynamic/static balance).

- Strict tolerances (diameter/thickness error <1mm).

- Customization: Diverse tooth patterns for varied pulp types and refining stages.

- Packaging:Clearly labeled with specifications and certifications.

6. Installation & Usage Guidelines

- Bolts: Avoid reusing old bolts; ensure uniform tightening to prevent imbalance.

- Handling: Use care during transport; clean installation surfaces.

- Operation:

- Avoid running without gaps.

- Remove debris from slurry to prevent damage.

- Halt operation if automatic controls fail.

- Installation Order:

- Follow numbered sequence (clockwise) for balance.

- Do not mix disc groups (thickness variations between groups).

7. Compatible Refiner Models

- Andritz:TF20, TF26, TF34, TF42, TF45, Deflaker A1850/C18K50.

- Voith: TF1E–TF4E Series; Deflaker E1K, E2000, E4000, E8000.

- Valmet: JC00–JC05, PRO1–PRO3.

-Yunda: Customize according to drawing specifications

Conclusion

Selecting the appropriate Refiner Disc—considering tooth profile, material, and compatibility—is vital for optimizing papermaking efficiency, minimizing downtime, and ensuring product quality.

OTHERS

2026

01-23

2026

01-09

2025

12-29